HEAVY DUTY DRIFT ELIMINATORS

EXPERT COOLING TOWER MAINTENANCE, REPAIRS, PARTS, & CLEANING!

COOLING TOWER DRIFT ELIMINATORS BY COOLING TOWER PRODUCTS

CALL COOLING TOWER PRODUCTS IN ARIZONA AT 602-268-1584!

If you’re searching for “Drift Eliminators”, “Cooling Tower Drift Eliminators” or “Heavy Duty Drift Eliminators“, while looking for cooling tower drift eliminator suppliers, Cooling Tower Products Can Help! We sell PVC, Cellular and other types of cooling tower drift eliminators. Our drift eliminators are designed to outlast O.E.M. and other aftermarket Dura Drift Eliminators for Evapco, Marley, and BAC cooling towers. Have questions? Give us a call today at 602-268-1584.

HEAVY DUTY DRIFT ELIMINATORS

THE HEAVY DUTY DRIFT ELIMINATORS THAT WE OFFER COME DESIGNED TO OUTLAST AFTERMARKET AND O.E.M. DRIFT ELIMINATORS.

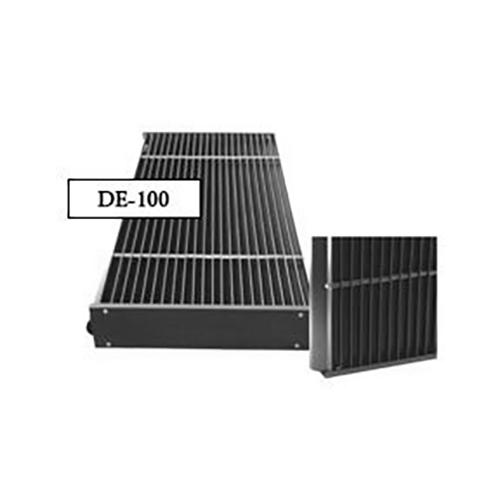

We have a full supply of our heavy duty drift eliminator blades in house ready to build to your towers specs. Our lead time is low and most orders are going out in 1-2 weeks. Our DE-100MAX eliminators can be used on all manufactured cooling towers, and condensers. We use stainless steel hardware and extruded PVC blades which makes our DE-100s rigid, hail resistant, snow loading, can be walked on, and able to be removed for pressure washing maintenance and returned to service. I have attached a cut-sheet above of the DE-100MAX. Maintainable Efficiency & Longer Service Life by checking out our Cooing Tower Drift Eliminators.

DRIFT ELIMINATOR APPLICATIONS

Our Drift Eliminator Applications are made for all makes and models including Imeco, Vilter, Recold, BAC, Evapco, Marley, Recold, Frigid Coil, Tower Tech & More! They are also made for all types of cooling towers including the following!

- EVAPORATIVE CONDENSERS

- FORCED DRAFT COOLING TOWERS

- INDUCED DRAFT COOLING TOWERS

- FLUID COOLERS

- CLOSED CIRCUIT COOLERS

- CROSSFLOW COOLING TOWERS

- COUNTERFLOW COOLING TOWERS

DRIFT ELIMINATOR FUNCTION

All cooling towers loose water due to evaporation. With a drift eliminator a cooling tower’s evaporation is just water vapor and isn’t harmful to the environment. Drift in cooling towers is the unwanted loss of water from the system. A drift eliminator stops airborne water droplets from leaving the cooling tower and helps preserve water. The water in cooling towers carries chemicals and minerals which help prevent bacteria from growing. Containing these chemicals helps preserve the environment around your property. A drift eliminator forces the airborne water droplets to change direction and land on the blades. From here, the water drips back into the system.

DRIFT ELIMINATORS FOR SALE

Features Include: Supports 200 lbs., UV Stabilized, Pressure Clean, Hail Resistant, High Impact Extruded P.V.C., Stainless Steel (or) Brass Connecting Rod & Hardware, Pressure Wash / Return to Service, Maintain Efficient Cooling Tower Operation, and a 1 year Warranty!

HEAVY DUTY

DRIFT ELIMINATORS

Extruded P.V.C.

Standard O.E.M. Sizes & Custom Sizes

Heavy Duty – Counter Flow

CELLULAR

DRIFT ELIMINATORS

Thermal Formed P.V.C.

W-12″, 18 & 24″

L-12″ to 144″

Counter Flow – Cross Flow

LIGHTWEIGHT

DRIFT ELIMINATORS

Thermal Formed P.V.C.

W-12″, 18 & 24″

L-12″ to 144″

Counter Flow

CROSS FLOW

ELIMINATOR BLADES

Nested Single A & B Blades

Thermal Formed P.V.C.

B.A.C. CFT Towers

Cross Flow

DE-100 DRIFT ELIMINATOR SPECS

- Standard Blade Depth – 5.5″

- Blade Thickness – 0.60 / 0.65

- Eliminator Width – OEM or Custom

- Eliminator Length – OEM or Custom

- Hardware – Stainless Steel/Brass

- Connecting Rods – Stainless Steel/Brass

- End Cap Brackets – Stainless Steel

- Pop Rivets – Stainless Steel

- Blade – Extruded High Impact P.V.C.

- Blade Spacer – Extruded High Impact P.V.C.

- End Cap – Extruded High Impact P.V.C.

- Heat Deflection Temp – 165F

- Flame Spread – Self Extinguishing

- UV Stabilized – Yes

- Color (P.V.C.) – Black

CONTACT US TODAY FOR A FREE QUOTE!

All Cooling Tower Products that we offer come designed to outperform and outlast any other aftermarket and O.E.M. parts. If you have any questions, please call our office today at 602-268-1584.