Forced Draft Vs Induced Draft Cooling Towers

If you are searching for the differences and similarities between forced draft and induced draft cooling towers, this article is for you!

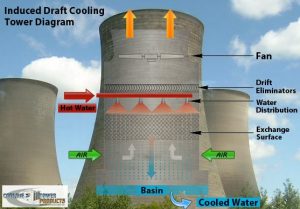

Induced Draft Cooling Towers

Induced draft cooling towers are a type of mechanical draft tower that features one or more fans. These fans will be located atop the tower, drawing air upwards against the downward flow of water. The water is passed around the wooden packing or decking. In these models, the coolest water is found at the bottom, coming in contact with the driest air since the airflow is counter to the water flow.

With the warmest water found near the top of the tower in contact with moist air, this results in an incredibly efficient transfer of heat. Induced towers will either come in round or square shapes, distributing water via a sprinkler or static branch system. Incoming water is injected throughout the tower with a spray distribution header. The spray is directed downwards in order to maximize the contact of water and air. This process is maximized by the cooling water fill, which is made up of wood, metal, PVC or other materials. In general, induced draft models offer the most effective solution to the cooling needs of any industry.

Induced Draft Cooling Tower Components

Most induced draft cooling towers will feature the following components:

- Spray nozzles.

- Fill.

- Basin.

- Piping.

- Casing/Shell.

- Fan.

- Drift eliminator.

Forced Draft Cooling Towers

There are many benefits of using a forced draft cooling tower. And that is exactly why so many industrial plants opt for this model over the other options. Forced draft cooling towers are very powerful and affordable at the same time. These models will remove low-potential heat that is generated in the production process. A counterflow of air combined with hot water results in a transfer of heat in the cooling fill. Paper and chemical industry plants often prefer to used forced draft cooling towers.

Forced Draft Cooling Tower Components

Here is a look at all of the components making up a forced draft cooling tower:

- Fan stack.

- Fan with drive.

- Cooling fill.

- Drift eliminators.

- Outer shell.

- Water basin.

- Water distribution system.

Forced Draft Vs Induced Draft Cooling Towers

So, how do forced draft models differ from induced draft towers? Induced draft versions feature a fan at the top of tower, pulling the air upward. Fans in induced draft cooling towers then induce the hot, moist air out of the discharge. A powerful exit air velocity reduces any possible recirculation within the tower as the end result. That is the main goal for these models: to eliminate the possibility of any discharged air flowing back into the air intake area.

Induced draft implies an inlet fan placed atop the tower, which creates low pressure. Forced draft, meanwhile, features an exhaust fan at the base of tower. This will then create the overpressure. Both centrifugal and axial fans can be used in forced draft models.

Induced Draft Features

- Low-absorbed capacity.

- Higher noise level than forced draft.

- Humid air stream drive.

- Requires little space for installation.

Forced Draft Features

- Ease of maintenance.

- Lower noise levels.

- Dry air stream drive.

- Low-absorbed capacity.

Cooling Tower Installation, Replacement, & Refurbishment in Arizona & Nevada

Our team offers complete cooling tower refurbishment that will save your company tens of thousands of dollars over buying and installing new cooling towers. Cooling tower refurbishment and rebuilding adds about another 15 years of life to your equipment and helps you get your money’s worth out of your original investment in your cooling tower or property. We offer cooling tower installation, replacement, and refurbishment in Arizona and Nevada. We also sell other cooling tower parts and products.